Add to Cart

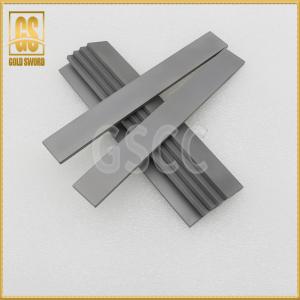

Cemented Tungsten Carbide Strips

Widia Cemented Tungsten Carbide carbide Rectangular Wear Strips for Cutting Wood / Metal

For details of this product, please click More:

1. Suitable for treating solid wood, shaving board and middle-density fiberboard.

2. Be used to make woodworking tools, such as forming tool, reamer, serrated knife blade and various blade.

3. suitable for machining hard wood, original wood as well as aluminum section bar, brass rod.

4, Mainly used as cutting tools for semi-automatic lathe, automatic lathe and planning machine.

5, Used as VSI rotor tips for stone crushing machine.

6, Applied as Plastic and tobacco cutters.

7, Widely used as Guide rail for centerless grinding machine.

8, Tungsten carbide strip is also suitable for the production of various types of motors, electronic progressive dies punches, etc.

|

GSGrade | ISO Grade | Density (g/cm3) | Hardness (HRA) | T.R.S (MPα) | Grain Size | Performance & Application Recommended |

| RX10 | K20 | 14.6-15.0 | 90~90.5 | 2200~2400 | Medium | High hardness, suitable for roughing of iron, solid wood, dry wood or nonferrous metal, ceramic and other alloys. |

| RX20 | K30 | 14.6-15.0 | 90~90.5 | 2600~2800 | Fine | It has high hardness, good toughness and good overall performance. It is suitable for processing all kinds of solid wood, mahogany, medium density board, non-ferrous metal, gray cast iron, etc. |

| RX10T | K10 | 14.6-15.0 | 92.5~93 | 1800-2000 | Ultrafine | High hardness, suitable for finishing of iron, nonferrous metal, ceramic and other alloying, semifinishing of of hardwood, chipboard, MDF and HDF. Better to use silver soldering. |

| AB10 | K40 | 13.8-14.2 | 87.5~88 | 2800~3000 | Coarse | High toughness, difficult to break tooth. Special used for finger jointing tool. |

| YN15 | K40 | 14-14.2 | 85-86 | 1700-1900 | Medium | Mainly used for stamping moulds and ceramic die of electronic components, petroleum machinery corrosion resistant instrument, without magnetic.

|

| SK40S | K10 | 14.5 | 91 | 3000-3200 | Fine | High On the basis of ensuring high bending strength, the wear resistance of the alloy is improved, the cutting edge is dense and sharp, which is conducive to the flatness of processing, and has good welding performance. It is used for food package, printing, aluminum foil, metalized film, and gardens. , Textile, leather, plastic, rubber and other mechanical blades. |

About Tungsten Carbide Square Bar :

The main composition of tungsten carbide bars or Hard Alloy Strips is tungsten carbide powders and cobalt powders .With its wear resistant and corrosion resistant ability , tungsten carbide nowadays is widely used in many areas such as : cutting tools , moulds , oil and automobile industry etc .

Tungsten carbide strip and bars is used as the cutter for the TCT woodworking knives for cutting all kinds of original wood , hard wood , HDF, MDF , plywood , particle board , laminated board, composite material ,grass, aluminum and metals . It can give much more excellent performance than HSS .

Cemented carbide strips are mainly made of WC tungsten carbide and Co cobalt powder mixed by metallurgical method through powder making, ball milling, pressing and sintering. The main alloy components are WC and Co. The content of WC and Co in the carbide strips used for different purposes is different, and the application range is very wide.